Civil Engineering with Computer Application | Electronics and Computer Science | Robotics & Artificial Intelligence |

Civil Engineering with Computer Application | Electronics and Computer Science | Robotics & Artificial Intelligence |

Important Documents For Admission (2025 - 2026)

Civil Engineering with Computer Application | Electronics and Computer Science | Robotics & Artificial Intelligence |

Civil Engineering with Computer Application | Electronics and Computer Science | Robotics & Artificial Intelligence |

| Degree Awarded | Discipline | Duration | Entry Level | Seats in IIST |

| B.Tech | CM | 4 years | 10+2 (PCM) | 60 |

The Department of Chemical Engineering of IIST, Indore is well known for providing a challenging academic program to its students. We also encourage our students to gain real-world engineering experience through industrial visits & projects etc.. Moreover, our graduate course offers exciting and multi-disciplinary opportunities for students to research and explore. Students at IIST get excellent opportunities to work alongside their advisors. IIST has state-of-the-art teaching tools and smart ICT resources. The department also offers specializations in different areas to its undergraduate students as well.

A graduate of the Chemical Engineering Program will demonstrate:

Ability to analyze different physical, chemical and biological systems/processes by applying the knowledge of unit operations and unit processes.

Ability to automate and control processes/systems by designing an environment friendly system for effective reaction, separation and purification and other operations in various processes with proper safety measures using modern engineering tools and simulators

Ability to acquire high end industry centric skills in the field of Chemical Engineering with professional ethics for the benefit of society.

Chemical Engineers are responsible for developing new industrial processes and designing new process plants and equipment or modifying existing ones. The role of chemical engineers is to design and troubleshoot the production processes through process automation, waste and energy management. They are often employed by large scale manufacturing plants to increase productivity and product quality while reducing costs. Along with the production industries and technical advancements, demand of skill graduate engineers is also increasing. In the view of this demand, our department has constituted 7 SIG’s for the students. In which they will get the

opportunity to upgrade their skills according to their interest.

1) SIG- Computational Analysis Techniques

Students are trained in high level critical and creative thinking skills. With the help of SPSS and EXCEL software they can solve chemical industries numerical problems with the ease.

2) SIG- Process & Instrumentation Design

Students will learn about the operations of various instruments used in the chemical industries, how to read and draft piping and instrumentation diagrams which is the very crucial step in any process industry. With the help of AutoCAD P&ID software and EXCEL students will able to do piping design like line sizing for liquid, gas and fluid mixtures.

3) SIG- Clean Energy

Through this SIG students will get knowledge about renewable energy technologies like Fuel Cell, Solar cells, Bio Energy etc., Live models will be prepared for domestic and Industrial purpose.

4) SIG- Process Integration with Pinch Technology

Students will learn about the “Systematic and general methods for designing integrated production systems, ranging from individual processes to total sites with special emphasis on the efficient use of energy and reducing environmental effects”. The main aim of this SIG is to teach students how to reduce the operating cost of existing plants, while new processes often can be designed with reduction in both investment cost and operating cost. Hands on training on MATLAB, CHEMCAD, ASPEN EDR-HTRI, ASPEN HYSIS, AFT Fathom, DWSIM software.

5) SIG- Industrial safety Management

This SIG aims in designing and operation of safe and cost-effective processes. Student will be educated about personal protective equipment, fire safety, hazardous materials and their symbols. Students will gain insights to recognize the importance of a safe work environment with live Industrial training.

6) SIG- AI/Machine Learning in Process Industries:

Students will able to adopt Machine Learning / AI techniques in chemical industries, like statistical machine learning, evolutionary computation in petroleum product characterization, chemical change modeling and process optimization, decision-making, environmental perception, and digital troubleshooting of varied problems within the industry. Coding skills will be given by PYTHON software

7) SIG- Nano Technology for waste management

Under this SIG student will able to learn state of the art techniques used in waste management like Nanotechnology and using smart polymers. Skills will be developed in synthesis and characterization techniques like XRD, FT-IR, SEM , UV Spectroscopy, HPLC, Gas Chromatography.

Dr. Samatha Singh

Head of Department

Chemical Engineering

Cont: 0731-4010674, 655

Email: [email protected]

LinkedIn: https://www.linkedin.com/in/samatha-singh-47a788148/

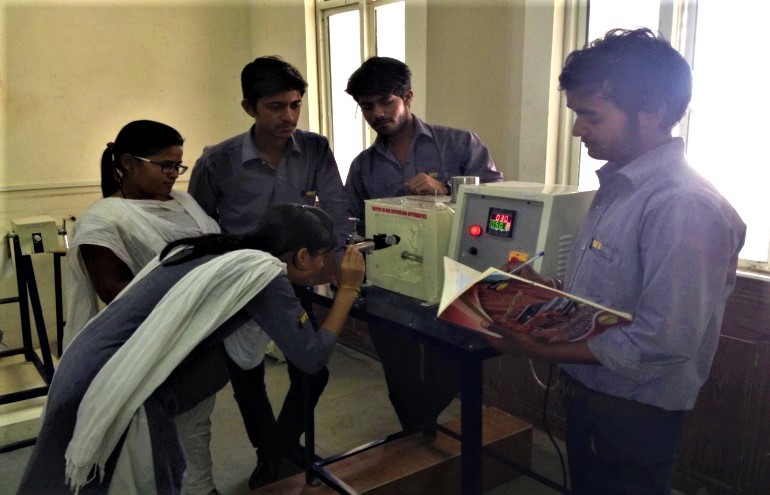

Welcome to the exciting world of Chemical Engineering! The Department of Chemical Engineering was started in the year 2012 In Indore Institute of Science & Technology, Indore. Chemical Engineers take a unique view of processes – they have the ability to look at processes which convert raw materials into useful products – both from an overall perspective, determining the economic feasibility of such conversion processes, but also from a very fundamental perspective, where the role and behaviour of specific components participating in these processes are studied in detail. This is what makes Chemical Engineering unique and relevant. Our students are exposed to practical problems through the department’s well equipped laboratories including Software Laboratory for advanced computation and simulation using software like CHEMCAD, AFT Fathom, AutoCAD P&ID, and MATLAB etc.

Industrial tours and in-plant training are organized in reputed chemical plants for our B.Tech Students every semester to link smart classroom teaching with chemical plant operation. Variety of workshops and guest lectures on advanced/emerging topics in Chemical Engineering are also organized for students. Reputed firms visit our campus to recruit the graduating engineers. Chemical Engineers are at the forefront of technology and their role in modern society is becoming increasingly important. Chemical Engineering Department at IIST takes pride in nurturing high quality Chemical Engineering professionals for fruitful engagement in industry, research and academics. I trust that you will find Chemical Engineering as interesting, challenging and relevant as many others before you have.

Industries

Research areas

Department of Chemical Engineering

List of publications of faculty

| S. No. | Name of Faculty | Title Name | Name of Journal | Publication Date |

| 1. | Mrs. Samatha Singh | A review on various MFC for power generation | Journal of Biofuel and Bioenergy | June 2016 |

| 2. | Mrs. Samatha Singh | Production of biodegradable plastic (polylactic acid) from mollasses | International journal of engineering science and humanities | 2012 |

| 3 | Mrs. Samatha Singh | A review on MFC using organic waste as feed | CIB Tech Journal of biotechnology | 2012 |

| 4 | Mrs. Samatha Singh | Advance oxidation process for waste water treatment: A Review | International Journal of Innovative Research in Science,Engineering and Technology | January 2019 |

| 5 | Mrs. Samatha Singh | Production of an Organic fertilizer from Garden waste | Journal of Emerging Technologies and Innovative Research | May 2019 |

| 6 | Mr. Rahul Gupta | Review on Reactive Distillation and Recent Applications

|

Imperial Journal of Interdisciplinary Research | November 2016 |

| 7 | Mr. Rahul Gupta | “Hydraulic Speed Breaker Power Generator” | International Journal of Engineering Research & Applications, Volume 3, Issue 6. | November- December 2013 |

| 8 | Mr. Rahul Gupta | Production of an Organic fertilizer from Garden waste | Journal of Emerging Technologies and Innovative Research | May 2019 |

| 9 | Rahul Bhargava | Techniques Available for the Extraction of Essential Oils from Plants: A Review | International Journal for Research in Applied Science &Engineering Technology(UGC Approved) | March-2018 |

| 10 | Rahul Bhargava | Production of Ethanol from Corn using Yeast

( Saccharomyces Cerevisiae) |

International Journal of Innovative Research in Science,Engineering and Technology, Volume 5, Issue 12. | December 2016 |

| 11 | Rahul Bhargava |

“Production of Biofuel (Ethanol) from Corn and co product evolution”: A Review |

International Research Journal of Engineering and Technology (IRJET) Volume 3, Issue 12. | December 2016 |

| 12 | Rahul Bhargava | A review on :Electro Coagulation technique on Dairy Waste water Treatment | Imperial Journal of Interdisciplinary Research | November-2016 |

| 13 | Rahul Bhargava |

A Review On: Comparison between Different Techniques for Treating Wastewater |

Imperial Journal of Interdisciplinary Research | November-2016 |

| 14 | Mr. Rahul Bhargava | Advance oxidation process for waste water treatment: A Review | International Journal of Innovative Research in Science,Engineering and Technology, | January 2019 |

| 15 | Mr. Rahul Bhargava | A compressive study on solid and Hazardous waste Management | International Journal of Innovations In Engineering Research & Technology | March 2019 |

| 16 | Mr. Rahul Bhargava | Recent methods available for rerefining of lubricating oil: A review | International Journal for Research in Applied Science &Engineering Technology | April 2019 |

| 17 | Pankaj Malviya |

Evaluation of water quality of Narmada river with reference to physico-chemical parameters |

International journal of engineering sciences & research technology |

2015 |

| 18 | Pankaj Malviya | Physico- chemical parameters of Narmada RiverWater: A review | International Journal of Chemical Studies | 2015 |

| 19 | Pankaj Malviya | Production of bio-plastic from food waste | IRJET | Under Process |

| 20 | Pankaj Kumar | Advance oxidation process for waste water treatment: A Review | International Journal of Innovative Research in Science,Engineering and Technology, | January 2019 |

| 21 | Pankaj Kumar | A compressive study on solid and Hazardous waste Management | International Journal of Innovations In Engineering Research & Technology | May 2019 |

| 22 | Farhin Khan | A Review On Technicques Available For The Extraction of Essential Oils From Various Plants | International Research Journal of Engineering &Technology | May 2018 |

| 23 | Farhin Khan | Study of Essential oil extraction from Eucalyptus and Lemon grass using hydro distillation method. | International Research Journal of Engineering & Technology | March 2019 |

| 24 | Mrs. Samatha Singh | Design of Sewage Treatment Plant for Small Town | International Journal for Research in Applied Science & Engineering Technology |

May 2020 |

| 25 | Mrs. Samatha Singh | Graphene as electrode material for the greater power generation in microbial fuel cell | International Journal of Chemical & Petrochemical Technology (Scopus) |

2019 |

| 26 | Mrs. Samatha Singh | Microbial fuel cell: a novel technology for energy generation and comparison of power densities for different electrodes using nano technology | Elsevier | 2019 |

| 27 | Mr. Rahul Gupta | Design of Sewage Treatment Plant for Small Town | International Journal for Research in Applied Science & Engineering Technology |

May 2020 |

| INDUSTRIAL TOUR | |||

| S. No. | Industry Name/ Research Centre | Date | Type of Company |

| 1 | Rama Phosphate Ltd. Dharampuri, Indore | 4th Oct. 2019 | Private Limited |

| 2 | Hindustan Petroleum Corporation Ltd. Magliya | 9 Feb.2019 | Government |

| 3 | Jalud Water Treatment Plant Visit | 29-Apr-17 | Government |

| 4 | Raja Ramanna Centre for Advanced Technology (RRCAT), Indore | 27 Jan. 2017 | Research centre |

| 5 | Symbiotic Pharma Pvt. Ltd. Indore | 22 Oct., 2016 | Private Limited |

| 6 | Sanchi Dugdh Sangh, Mangliya, Indore | 12-Mar-16 | Public Limited |

| 7 | Wind Mills, Dewas | 6 Nov., 2015 | Government |

| 8 | Tata International Ltd., Dewas (M.P) | 12-Mar-15 | Exporter / Manufacturer / Supplier |

| INDUSTRIAL TOUR | |||

| S. No. | Industry Name | Date | Type of Company |

| 1 | K.C Engineers | 27th – 3rd April,2016 | Pivate Ltd. |

| 2 | Nuclear Power Corporation Of India Limited, Tarapur | 9th – 15th March ,2017 | Government |

| 3 | Hindustan Petroleum Corporation Limited (HPCL), Vishakapatnam , Vizag steel museum , submarine museum | 3rd – 9th March ,2018 | Government |

| 4 | Vardhman Textile Ltd. Baddi, Himachal Pradesh | 3rd – 10th January 2019 | Pivate Ltd. |

1. ISTE Students Chapter:

Providing quality training programmes to teachers and administrators of technical institutions to update their knowledge and skills in their fields of activity. To assist and contribute in the production and development of top quality professional engineers and technicians needed by the industry and other organizations. Providing guidance and training to students to develop better learning skills and personality.

Providing quality training programmes to teachers and administrators of technical institutions to update their knowledge and skills in their fields of activity. To assist and contribute in the production and development of top quality professional engineers and technicians needed by the industry and other organizations. Providing guidance and training to students to develop better learning skills and personality.

2. Swayam Students Chapter:

SWAYAM is an initiative by Ministry of Human Resource Development, Government of India. World’s largest SWAYAM MOOCs (Massive Open Online Courses), a new paradigm of education for anyone, anywhere, anytime, as per your convenience, aimed to provide digital education free of cost and to facilitate hosting of all the interactive courses prepared by the best more than 1000 specially chosen faculty and teachers in the country. SWAYAM MOOCs enhances active learning for improving lifelong learning skills by providing easy access to global resources.

SWAYAM is an initiative by Ministry of Human Resource Development, Government of India. World’s largest SWAYAM MOOCs (Massive Open Online Courses), a new paradigm of education for anyone, anywhere, anytime, as per your convenience, aimed to provide digital education free of cost and to facilitate hosting of all the interactive courses prepared by the best more than 1000 specially chosen faculty and teachers in the country. SWAYAM MOOCs enhances active learning for improving lifelong learning skills by providing easy access to global resources.

3. Indian Institute of Chemical Engineers:

Department of Chemical Engineering is proud to be associated with Indian Institute of Chemical Engineers (IIChE) as an organizational member. The IIChE publishes a quarterly journal, the Indian Chemical Engineer (ICE) and conducts annual session known as the Indian Chemical Engineering Congress (CHEMCON).