Civil Engineering with Computer Application | Electronics and Computer Science | Robotics & Artificial Intelligence |

Civil Engineering with Computer Application | Electronics and Computer Science | Robotics & Artificial Intelligence |

Important Documents For Admission (2025 - 2026)

Civil Engineering with Computer Application | Electronics and Computer Science | Robotics & Artificial Intelligence |

Civil Engineering with Computer Application | Electronics and Computer Science | Robotics & Artificial Intelligence |

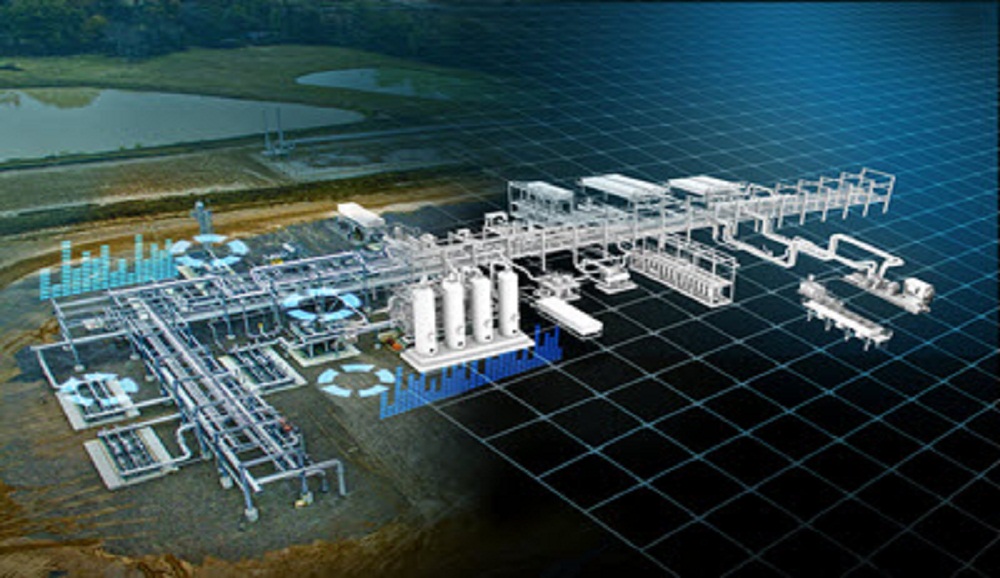

Process Simulation Software in Oil & Gas Industry ((Picture courtesy : OpenPR )

A typical chemical engineer uses Maths, Physics, Chemistry concepts to make medicines accessible, water drinkable, air breathable, environment sustainable, systems affordable, safety reliable. In this world where everything is automated and core engineers also required software skills for better process optimisation and controlling.

Commonly used SOFTWARE TOOLS in Chemical Engineering

MATLAB

MATLAB is one of the best software packages in Chemical engineering to plot data and for numerical calculations.

ASPEN

Is a process simulation software package widely used in industry today. ASPEN uses mathematical models to predict the performance of the process. ASPEN can handle very complex processes, including multiple-column separation systems, chemical reactors, distillation of chemically reactive compounds, and even electrolyte solutions like mineral acids and sodium hydroxide solutions.ASPEN does not design the process. It takes a design that the user supplies and simulates the performance of the process specified in that design. Therefore, a solid understanding of the underlying chemical engineering principles is required to supply reasonable values of input parameters and to evaluate the suitability of the results obtained.There are mainly 14 modules avialble in ASPEN and many other sub modules in each main module. Some of the most used modules are

A general process simulation and modelling software very commonly used in the upstream oil and gas industry is HYSYS. HYSYS is extensively used for developing PFD and mass and heat balance.

It is extensively used for modeling of flare or cold vent networks commonly required in upstream oil and gas. It allows to determine type of relief device and sizing of connected piping including individual tail pipes, flare sub-header and flare main header.

Aspen Exchanger Design and Rating (EDR) enables you to easily design and simulate the heat Exchangers. It delivers the heat exchanger rating and size optimally with respect to performance and economical aspects by integrating state of the art modelling techniques.

PIPESIM from SCHLUMBERGER

A simulation and modeling software used for steady-state modeling of “pipelines” both for single-phase, two-phase and three-phase flow.

PIPENET

PIPENET is used for the rapid fluid flow analysis of pipe and duct networks. Three modules (Standard Module, Spray/Sprinkler Module, Transient Module) ensure that, no matter how complex your network, PIPENET software will perform flow simulation fast and accurately.It is the leader in this category.

FluidFlow

FluidFlow software the most comprehensive ,uncomplicated and undemanded to use graphical interface.

FluidFlow has following modules;

CHEMCAD

It broadens the approach and scope of the chemical engineers everywhere with enhanced process simulation software, It is used to enhance the productivity by solving day to day tasks and can solve the most difficult process models with its flexibility in handling.

For more details https://www.chemstations.com/Support/Frequently_Asked_Questions/#Q1

AFT Fathom

For pressure drop calculations and pipe flow distributions AFT Fathom is one of the best. It can be used in low velocity profiles also. It can Model a wide range of system components for both design and operational cases. It has an additional feature that is can calculate the cost of system pipes and components

AutoCAD P&ID

For piping and Instrumentation diagrams AutoCAD P&ID software is the leader in category.Its simple and approach allows a process engineer to create, modify, and manage piping and instrumentation diagrams. Most complicated flow sheets and Diagrams become simple to understand with this software

Computational Fluid Dynamics (CFD)

As process Engineers has to deal with different types of fluids ,so to analyse their behaviour in different conditions is one of the toughest task ,CFD is the relief for this particular problem .It analyses laminar as well as turbulent flows, multiphase flows and compressible and Incompressible flows

For different types of CFD softwares follow the link: https://www3.technologyevaluation.com/sd/category/computational-fluid-dynamics-cfd

General Software packages used in Chemical Engineering

|

Mathematical Modelling |

Process Simulation |

Computational Fluid Dynamics |

|

MS-EXCEL |

Aspen HYSIS |

Autodesk CFD |

|

MATLAB |

CHEMCAD |

ANSYS Fluent |

|

SIMULINK |

Aspen Plus |

COMSOL Multiphysics |

There are more chances to get good jobs with better packages in process industries with the knowledge of chemical software’s.

Mrs.Samatha Singh

Head, Department of Chemical Engineering

Indore Institute of Science & Technolgy.